The Confusion That Costs Homebuyers

For decades, the words “modular” and “manufactured” have been tossed around as if they mean the same thing. They don’t.

This confusion leads countless homebuyers to underestimate what modular construction really is—and what it delivers. When people hear “modular,” they often picture a mobile home rolling down the highway, built to minimal standards and parked in a manufactured home park. But modular homes are a different story entirely.

At Wolf Industries, we’re redefining what it means to build in a factory. Modular construction isn’t about cutting corners – it’s about eliminating them.

Built to Code, Not on Wheels

Let’s start with the foundation of the difference: building codes.

Manufactured homes are built to HUD standards, which are national guidelines designed for homes built on a permanent steel chassis. These are technically classified as personal property – more similar to vehicles than real estate.

Modular homes, on the other hand, are built to the same International Residential Code (IRC) that governs traditional, site-built homes. That means they must meet or exceed every local building code, from seismic and snow-load requirements to fire safety, insulation, and wind resistance.

A modular home sits on a permanent foundation. It’s engineered to last for generations, not to be transported from place to place. Every module is inspected multiple times – first within Wolf’s factory, then again by state and/or local officials before keys are handed over and it becomes a home.

In short: Manufactured homes are vehicles. Modular homes are real homes.

Precision Over Guesswork

Ask any builder where things go wrong on a traditional jobsite, and they’ll tell you: it’s the weather, the scheduling, and the guesswork. Materials left in the rain. Crews juggling multiple jobs. Delays piling up before the walls are even framed.

That’s where modular construction shines.

At Wolf, our homes are built indoors – protected from the elements and assembled by specialized teams who repeat each step of the process every single day. It’s not rushed, it’s refined. Each build moves through defined phases of production, with dedicated stations and experienced professionals checking every inch for quality and precision.

The result is consistent craftsmanship. No warped lumber, no delays, and no weather-related surprises. Just a home built exactly as designed – every time.

And because Wolf handles engineering, permitting, production, delivery, and setup in-house, our process doesn’t stop at the factory door. Your home is built with local codes in mind, for your exact site conditions.

Stronger by Design

One of the biggest misconceptions about modular homes is that they’re “lighter” or “less durable” than site-built homes. In reality, the opposite is true.

Every modular home must be strong enough to be craned, shipped, and transported on public highways – meaning it’s built with additional structural reinforcement throughout the frame. That added strength translates into long-term durability once it’s placed on its foundation.

Walls are straighter. Floors are quieter. Seams are tighter.

That structural integrity also creates a tighter building envelope, which improves energy efficiency. Wolf homes are designed to retain heat better in the winter, stay cooler in the summer, and reduce energy costs over time – all while meeting or exceeding state efficiency standards.

Every stage of production is guided by Wolf’s Proven Process, ensuring your home isn’t just built fast – it’s built right.

From Factory Floor to Finished Foundation

You can measure reliability in more than words – you can see it in results.

Our modular homes have proven themselves in some of the most challenging environments imaginable. In Teller, Alaska, we delivered and installed four modular homes near the Arctic Circle, where freezing temperatures, remote logistics, and permafrost foundations tested every ounce of our process. Those homes weren’t just delivered – they’re now thriving, permanent residences for Native Alaskan families.

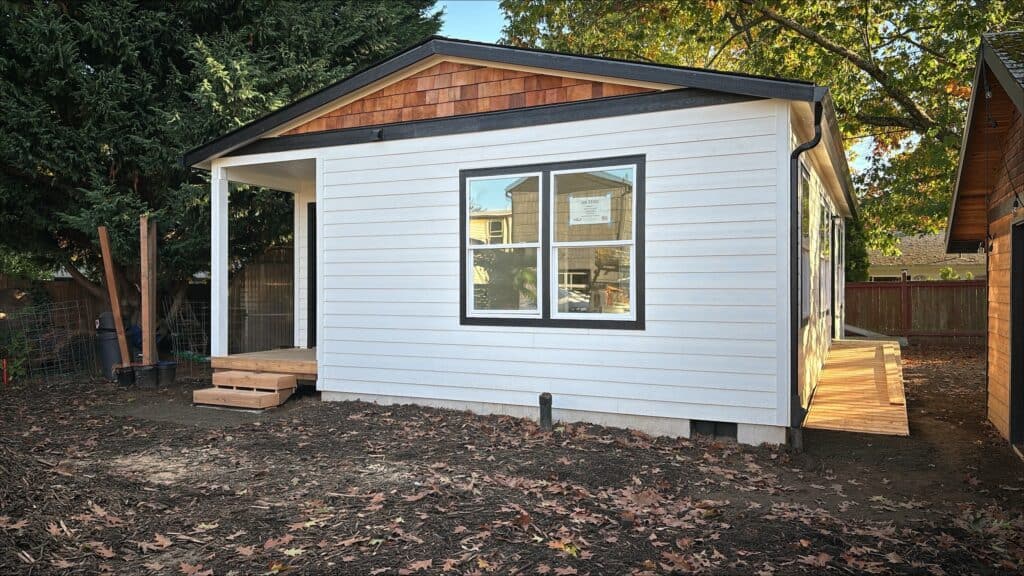

In the Pacific Northwest, our modular cottages in communities like The Orchards District and Image District Cottages showcase how scalable, repeatable, and reliable our process is. Each home was built indoors, shipped to the site, and placed in weeks – not months – without compromising quality or aesthetics.

From the first permit to the final inspection, Wolf’s turnkey approach removes uncertainty and delivers results that can’t be matched by traditional or manufactured housing.

Smart Buyers Go Modular

Modular homes aren’t just faster – they’re a smarter long-term investment.

Because they’re built to residential building codes, they qualify for traditional home financing and standard appraisals. They also appreciate in value just like a site-built home, not depreciate like a manufactured one.

And since factory-built efficiency reduces construction waste, labor downtime, and costly weather delays, you’re not just buying a home – you’re investing in a more reliable process.

Let’s bust a few myths while we’re at it:

- Myth: Modular homes are mobile.

Reality: Once set, they’re permanent – built on solid foundations and designed for a lifetime. - Myth: Factory-built means cookie-cutter.

Reality: Wolf’s modular homes are customizable, modern, and crafted with precision inside a controlled environment. - Myth: Modular homes are cheaper because they cut corners.

Reality: They’re more cost-efficient because they eliminate waste, not quality.

Built Different. Built in a Factory.

At Wolf Industries, modular isn’t a buzzword – it’s a commitment.

We build homes that last longer, perform better, and deliver faster than anything built in the mud and rain. Our factory process ensures reliability. Our engineering ensures precision. Our people ensure quality.

That’s the modular difference.

That’s the Wolf difference.

Ready to see it for yourself?

Schedule a shop tour or explore our models to discover how we’re building the future of housing – one module at a time.