Think about the last time you drove past a never-ending job site. Trucks coming and going. Materials sitting in the rain. Neighbors wondering when the mud will end. Now imagine a different picture. Your foundation and utilities are going in while your home is being built in a clean, controlled environment. The day your modules arrive, a team sets them on the foundation, crews button up the seams, utilities get hooked up, and your yard looks like a project nearing completion rather than just getting started. That is the modular advantage for a full-size primary home.

Modular vs Stick-Built

Modular is a construction method, not a style of home. Your house is built indoors in sections called modules, then transported to your property and installed on a permanent foundation. The result is a real home with the same curb appeal and interior comforts of a traditionally built home. The difference is how it gets built and how that build method impacts your timeline, your budget, and your day-to-day life during construction.

Faster Build Times and a Cleaner On-site Experience

Speed matters when you are carrying a construction loan, storing furniture, or living with family until move-in. Modular compresses the schedule in two ways. First, factory production follows a predictable workflow that does not pause for weather delays. Second, site work can progress at the same time your home is being built off-site. This parallel path reduces the number of open calendar days your property is a construction zone. Fewer vehicles in your driveway. Fewer days with crews on site. More control over when you can move in.

A faster build is not just about convenience. It is also about reducing risk. Every extra week is another opportunity for costs to creep, materials to get damaged, or schedules to collide. A method that shortens the window lowers the chance of those surprises.

Same Quality Materials

A common misconception is that modular means “lesser materials.” In reality, your home is built with the same types of framing lumber, sheathing, insulation, windows, doors, roofing, cabinets, fixtures, and mechanical systems that you would expect in a traditional build. The difference is consistency. Indoors, carpenters work with precision jigs and repeatable stations. Dry materials behave predictably. Installers can apply standardized best practices without improvising around mud, wind, or a weather-soaked subfloor. The net effect is a fit and finish that looks and feels tight from day one.

Better Quality Control

Quality control starts with the environment. Wood that does not get rained on. Finishes that cure at stable temperature and humidity. Tradespeople that can work in sequence without weather interruptions. In a factory, each stage is checked before the module moves forward. That creates a rhythm of inspection that is hard to replicate in an open-air site. Over time, this shows up in straighter drywall seams, crisp trim lines, cleaner mechanical runs, and reduced call-backs.

Permitting and Building Simultaneously

Traditional construction typically runs in a series. Design, then permitting, then building, then finish. Modular lets you run two tracks in parallel. While your permits move through the jurisdiction, your home is being built indoors. Meanwhile, your property can be getting its foundation, utilities, and driveway prepared. When approvals are ready, you are not starting from zero. Modular builders coordinate delivery, house set, connections, and final inspections. This overlap squeezes idle time out of the process and keeps momentum.

Comparable Sizes to Stick-built Homes

Modular is not synonymous with tiny. It ranges from compact cottages to full-size family homes. The right plan uses modules as building blocks to create rooms that feel generous and sensible for daily life. Think full living rooms that welcome a real sofa, dining areas that seat guests comfortably, kitchens with proper storage, and bedrooms that do not feel like hallways. The point is not to compromise how you live. It is to change how your home is built.

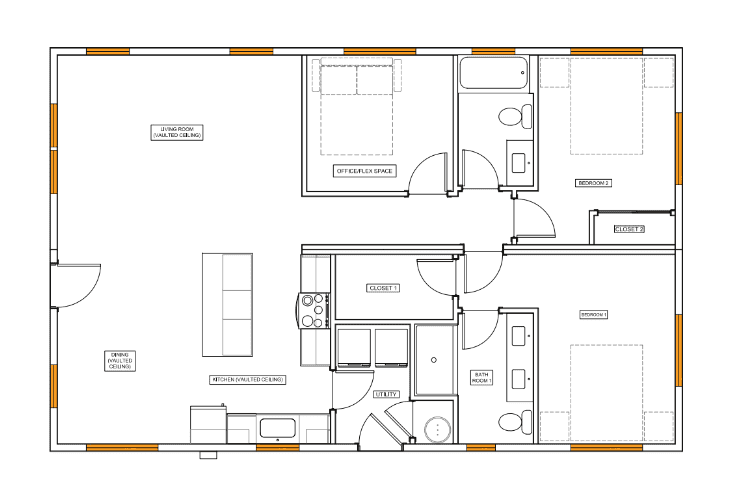

Spotlight on a Full-size Layout: Model I at 1,230 sq ft

To visualize what “full-size” looks like in practice, look at Wolf’s Model I. At 1,230 square feet, the Model I demonstrates how modular can deliver a primary residence with a real sense of space. The plan is designed for everyday livability, with an easy flow through the main living areas and a layout that can support the features homeowners ask for most. If you want a home that feels open, organized, and move-in ready without months of on-site chaos, the Model I shows how modular makes that possible.

Cost Savings Over Traditional Builds

There are three places modular can save money. First, efficiency. Indoor workflows, repeatable stations, and bulk purchasing can reduce waste and rework. Second, time. A shorter build window can trim carrying costs, from loan interest to storage and temporary housing. Third, predictability. More work happens in a standardized environment where labor and materials are scheduled tightly, so budgets set earlier in the process are more likely to hold.

Cost savings should be discussed honestly. Site work, utility distances, and custom selections will always influence the final number. The value of modular is that your core structure is built in a way that systematically removes many of the delays and variables that inflate costs in traditional builds.

Life During the Build, and After

Your life matters during construction. Modular reduces noise, traffic, and yard wear because the most labor-intensive phases happen away from your property. When installation day arrives, it feels like a milestone rather than the start of a long slog. After move-in, you live in a home that was assembled with clean, dry materials and consistent craftsmanship. Over the long haul, that can translate into fewer squeaks, straighter lines, and a finish that holds up.

The Process – First Call to Move-in

Feasibility. Begin with a property evaluation to confirm utility access, setbacks, and any site constraints that could affect placement or foundation design. This step aligns expectations and surfaces early questions.

Predesign and selections. Choose your plan and the finishes that fit your taste and budget. Talk through any accessibility or convenience needs so the plan supports how you live.

Permitting and production in parallel. While your permits move through the local process, your modules are built indoors and your site work begins. This is where modular compresses the schedule.

Delivery, set, and connections. On delivery day, modules are placed onto the foundation. The crew unifies the structure, completes roof seams, and ties in mechanicals. Your property looks like a nearly complete home rather than a bare slab.

Final walkthrough and handoff. Inspections are completed. You review the home with the team, note any touch-ups, and receive keys along with basic maintenance guidance.

Why It Matters

Markets change. Interest rates move. Labor and materials fluctuate. What does not change is the value of a process that removes uncertainty. Building indoors with a predictable workflow, while your site advances in parallel, gives you control over the two variables homeowners worry about most: time and money. Add the comfort of a full-size plan like the Model I at 1,230 square feet, and you have a practical path to your primary residence without the usual drama.

Getting Started

Explore the Model I to see how a full-size modular plan looks and lives. Share your property details to get a feasibility read. If the fit is right, you will have a clearer timeline, a realistic budget path, and a plan that respects your life during construction as much as it does after move-in.

Ready to turn the messy, open-ended build into a clean, predictable process? The modular method is designed for that. Start with our free property evaluation.